Product Details

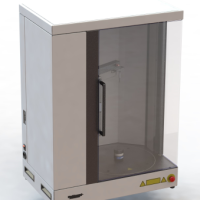

C-CELL COLOUR

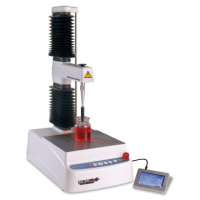

What is the cutting edge, convenient and comprehensive method of quality testing bread and baked products? The C Cell Colour is an advanced digital imaging system that gives you the capability to assess the quality of products, ingredients and process conditions. This instrument takes a high-resolution colour image of the baked food sample and uses it to provide detailed, objective and easily readable data.

Use the Calibre Control C Cell Colour to test for:

- Internal structure

- External feature

- Number of cells

- Net cell elongation

- Non uniformity

- Cell diameter

- Number of holes

- Wall thickness

- L*a*b* crumb colour

- Bread scoring

- Internal inclusion analysis

Applicable on:

- Bread

- Cake and biscuits

- Snack food

- Aerated products

Why choose the C Cell Colour?

- The C Cell Colour provides consistently reliable and repeatable analytical results while removing human error.

- It is a highly adaptable instrument with adjustable calibrations to suit the needs of your specific application.

- The C Cell Colour uses a bread scoring system which provides consistent results, regardless of site or circumstances.

- It provides quantifiable data, which you can use to score against your quality targets.

- It can provide more than 50 different quality results across a wide range of bakery products.

- The C Cell Colour is useful in demonstrating the impact of even slight changes in processes, production or ingredients on the structure of bread or baked products.

How does it work?

- Place the bread or baked food sample flat in a special draw mechanism.

- Once closed, it enables the C Cell to capture a high-resolution digital image of the sample.

- From this, the instrument can then provide a detailed data analysis using multiple measurements, which are viewable on-screen.

Why you should use the C Cell Colour

Quality testing and analysis of bread and baked products is essential to meet food standards and to ensure a consistent quality that consumers demand.

The C Cell enables the user to gain valuable, objective data for several critical parameters when it comes to analysing baked product quality, including:

- Softness – the C Cell can provide a texture profile analysis to characterise the softness of a sample

- Colour – the C Cell colour gives l*a*b* colour results and data such as internal crumb colour, external crust colour and depth

- Dimensions – multiple measurements for each sample slice including area, width and even optimum packaging dimensions

- Shape – the visual appearance of the sample, such as concavity, oven spring and shoulder and bottom roundness

- Moulding performance – crumb cell elongation measurements provide a visual guide to axis of elongation and level of curvature of the internal crumb structure and give a specific degree of circulation.

- Cell size – by measuring this, the C Cell can quantify holes, wall thickness, cell areas and volumes

Critical measurements for performance and quality

The C Cell Colour is the ideal fit for analysing and monitoring various baking processes and aspects, and baking products:

- Bakery production

- Cake and biscuit production

- Test baking

- Ingredients, such as improvers and yeast

- Research and development

- Snack food

- Flour milling

- Chocolate confectionary

- Bakery equipment manufacturing

- Research and plant breeding